Functional features

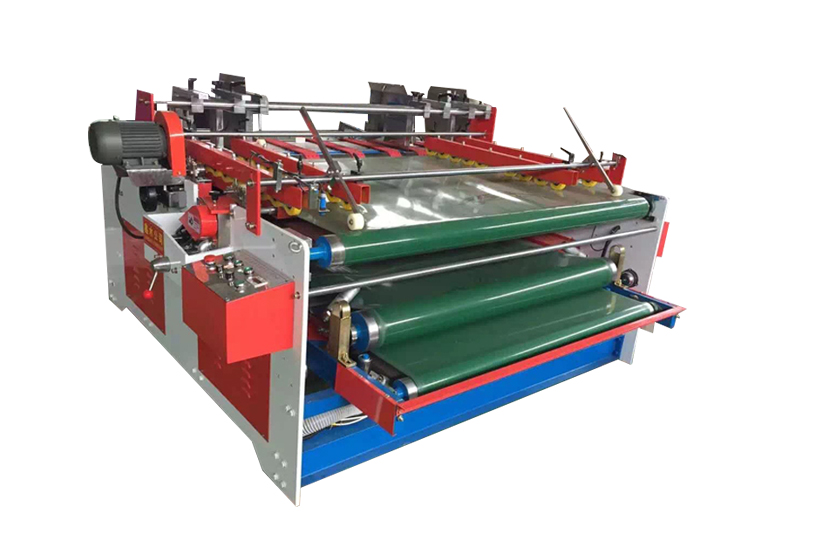

1120 automatic precoating paperboard laminating machine is a new product developed by our company according to the market needs. It is a model designed for the current precoating. The main machine integrates automatic paperboard feeding, fitting and breaking, which is convenient for operation. The machine integrates machinery, electricity and gas, operates stably and is convenient for operation and maintenance.

Structural features:

◇The whole machine is designed with small floor space and convenient operation.

◇Automatic paper feeding, automatic breaking, time-saving, labor-saving and high efficiency

◇The main composite roll adopts large-diameter steel roll and electromagnetic heating system, with uniform and stable surface temperature.

◇Order memory function, one click order change, saving time

◇The main engine adopts frequency conversion speed regulation and PLC control system, which can stably and flexibly adjust the working speed.

◇The servo control speed is adjusted by PLC according to the lap length.

Technical Parameters:

| Model | TB-1120FM | TB-1320FM | TB-1620FM | TB-2000FM |

| Max. Paper Width | 1050mm | 1250mm | 1550mm | 1950mm |

| Cladding temperature | 80-120℃ | 80-120℃ | 80-120℃ | 80-120℃ |

| Pressure | 0-8MPa | 0-8MPa | 0-8MPa | 0-8MPa |

| Speed | 0-50m/min | 0-50m/min | 0-50m/min | 0-50m/min |

| Overall Dimensions | 2000*5500*1600 | 2200*5500*1600 | 2500*5500*1600 | 2900*5500*1600 |

| Total Power | 20KW | 20KW | 20KW | 20KW |

| Weight | 3000KG | 3300KG | 3600KG | 4000KG |

Main Components And Origin :

| name | Brands and models | place of origin |

| Main Motor | 3.7KW | Zhejiang |

| Heating Roller | 300mm | Guangdong |

| Rubber Roller | 250mm | Guangdong |

| Bearing | NSK | Japan |

| Electromagnetic

Heating |

320mm | Wenzhou |

| PLC | Fatek | |

| Touch Screen | Fatek | |

| Switch | Electric | Zhejiang |

| Servo Motor | 1.5KW | Guangzhou |

| Power | Omron | Japan |

| Relay | Siemens | Germany |