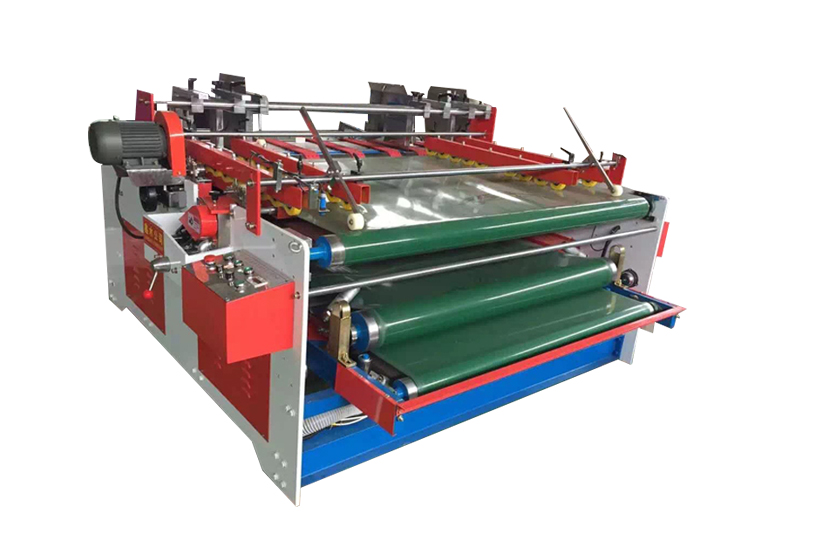

TB-Automatic rotary die cutting machine

The machine adopts automatic lead edge feeding system and double roller rotary type. It can perform all process of slitting, creasing, corner cutting and hit special hole at one time. It has advantage of high precision, easy to operate, high speed ,long service life and low cost.

Functional features

◇Automatic compensation device for linear speed of rubber cushion roller to prolong the service life of superior adhesive.

◇The lead edge feeding has the advantages of good stability, fast working speed, low failure rate and high efficiency.

◇ The rubber feeding roller with resorte device, feeding accurately, stably, not destroy paperboard strength if the feeding space is very small.

◇ The left and right side baffles adopt electric control , the back baffles adopt electric adjustment, the front baffle space manual sync adjustment.

◇ Equipped with colors touch screen take 360 degree set to die roller, display product speed and set production quantity.

◇Automatic lateral movement of cushion roller 40 mm from left to right, prolonging the service life of superior rubber

◇When the rubber pad is used unevenness, can open the function of the rubber roller, prolong the service life of the rubber pad.

◇ Adopt high-quality Germany Depair rubber pad.

◇The roller is made of cast steel, with a wall thickness of 45mm,

◇Pneumatic manual or automatic control of die cutting roll, die cutting roll to lift cutting paper, stop the paper feed to fall to avoid damage to the rubber pad.

◇ Electrically adjusted phase die-cutting position

◇The transmission gear is automatically sprayed and lubricated, and the service life of the gear is prolonged.

Technical parameter:

| Model | 1200*2400 |

| Max. Cardboard size | 1200×2400mm |

| Min. Cardboard size | 300×400mm |

| Total power | 7.5kw |

| Max. speed | 140pcs/min |

| Adoptable thickness of paperboard | 2-10mm |