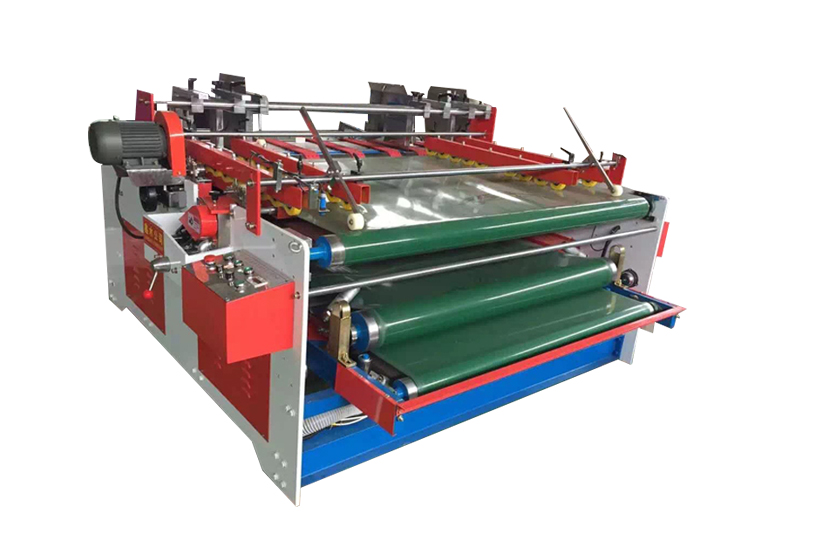

TB-1080 Automatic Die-cutting and Creasing Machine

型号:TB-MY1080

Functional features

◇This machine has a powerful four – suction and four – delivery feeder which can adjust the angle of suction with the paper deformation, and blow the paper separating device to facilitate paper separation.

◇Air separation device for paper separation.

◇Mainly used for cardboard, map, E、Bflute corrugated paper.

◇The main chain (Germany) adopts heavy load and high precision transmission chain, with very small production error, high tensile strength and wear resistance.

◇The gripper row is made of high quality superhard aluminum alloy profiles, and the surface is anodized to ensure the completion of die cutting process.

◇It has overload protection mechanism, to achieve accidental overload, active separation of the die – cutting board frame can effectively prevent the die – cutting board sagging and fall off.

◇Pneumatic lock plate mechanism adopts imported cylinder, stable performance, convenient and fast operation.

◇Intermittent mechanism can achieve smooth transmission, accurate indexing, and ensure the accuracy of die – cutting.

◇The electric control system is controlled by PLC and equipped with various safety protection devices, which can give audible and visual alarm in case of failure and shut down automatically, truly guaranteeing the man-machine safety.

◇The timing and quantitative automatic oil supply system can ensure the full lubrication of other moving parts of the machine and have long service life.

Technical parameters:

| Item | Parameters |

| Model | MY-1080 |

| Max paper transmitting size (mm) | 1080*760 |

| Min paper transmitting size(mm) | 400*380 |

| Max die cutting size(mm) | 1060*750 |

| Min gripper size(mm) | 7mm |

| Max die cutting pressure | 300N/cm² |

| Max die cutting speed | 7000 sheets/h |

| Max feeding pile height | 1200mm |

| Min feeding pile height | 1200mm |

| Main motor power | 11 kw |

| Total power | ~16.5 kw |

| Total weight | 15T |

| Overall size | 5580*2100*2220 |