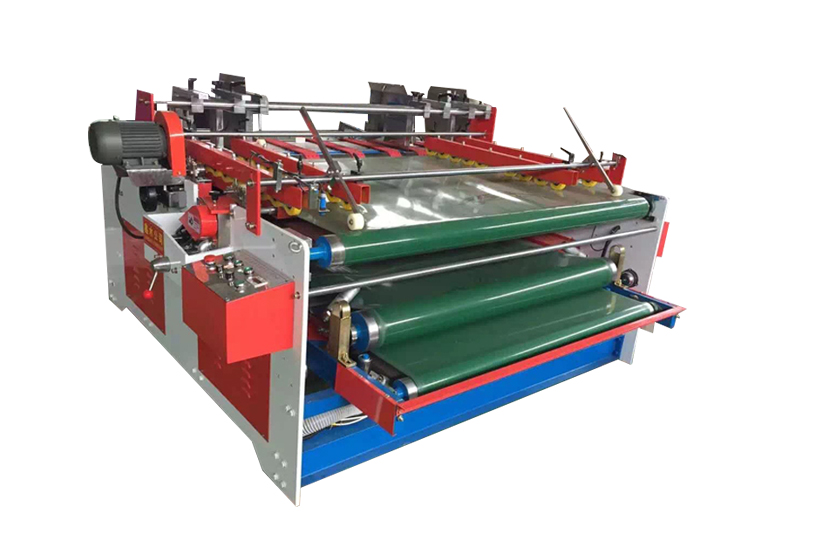

Automatic Stitching Machine

The automatic nail box machine is composed of paper feeding part, folding part, nail box part and counting output part. PLC computer control, one key adjustment of input data, order storage and simple operation., One key conversion, left and right electric traverse. The adjustment is convenient, fast and efficient.

Functional features

Feeding

The wallboard is welded with steel plate. The transmission shaft is welded with seamless steel pipe, the pipe wall thickness is 20mm, the shaft surface is plated with hard chromium, and the bearing is made in Wafangdian, Harbin. High pressure fan is used to feed the paperboard to ensure stable paper feeding. Each wear-resistant air suction belt can control the air volume separately to ensure the smooth feeding of paperboard. Drive synchronous toothed belt for paper feeding and smooth operation.

Folding

The folding part adopts two kinds of pressing: pre pressing wheel and forming wheel, and then re strengthens the paperboard pressing line on the original pressing line. The position is accurate, the paperboard is not broken, the folding is beautiful, and the flat belt is pressed, folded and the synchronous belt is used to transport the finished products smoothly.

Stitching

The servo motor of the nail box is independently controlled, with automatic paper feeding, automatic nailing and automatic counting. The machine head is made of special material, which is wear-resistant and stable with low noise. The head servo motor is directly driven with high speed and accurate nail distance. Large plate nail line reduces wire change time and improves work efficiency.

Correction unit

The bearing eccentricity correction (with differential correction) makes the paperboard folding beautiful, and the size of the correction part can be adjusted horizontally.

Counting output unit

Finished cartons are stacked and output, so that cartons can be output。and packaged smoothly.

Core technology

◇Fast carton forming speed

◇Accurate air suction and paper feeding

◇Secondary indentation makes the crease more accurate without fracture

◇The size of the mouth is well controlled to reduce waste products

◇Secondary deviation correction and elimination of scissors

◇Accurate counting

Machine parameters:

| Function | 钉箱 |

| Type | LC-3000 |

| Max.Dimension (a + b) X2 (mm) | 2800mm |

| Min.Dimension (a + b) X2 (mm) | 780mm |

| Max.Dimension (C + D + C) X2 (mm) | 1450mm |

| Min.Dimension (C + D + C) X2 (mm) | 380mm |

| Max. Width B (mm) | 600mm |

| Min. Width B (mm) | 160mm |

| Max. Length A (mm) | 900mm |

| Total Power (Kw) | 23kw |

| Min. Length A (mm) | 200mm |

| Nail Tongue Width E (mm) | 35-40mm |

| Machine Speed(Nail/Min) | 800钉/分钟 |

| Number of nails | 1-99 |

| Nail distance (mm) | 30-80mm |

| Nail box speed | 60米/分钟 |