Functional features

Technical parameters:

| Working width | 1800mm |

| Design speed | 200m/min |

| Economic speed | 100–150m/min |

| Glue volume adjustment range | 0.08-0.6mm |

| Number of anilox roller | 32 lines |

| Preheating cylinder temperature range | 150—200℃ |

| Working power | 380V 50Hz 9KW |

| Air source system | 0.4—0.9Mpa |

| Pressing method | Pneumatic |

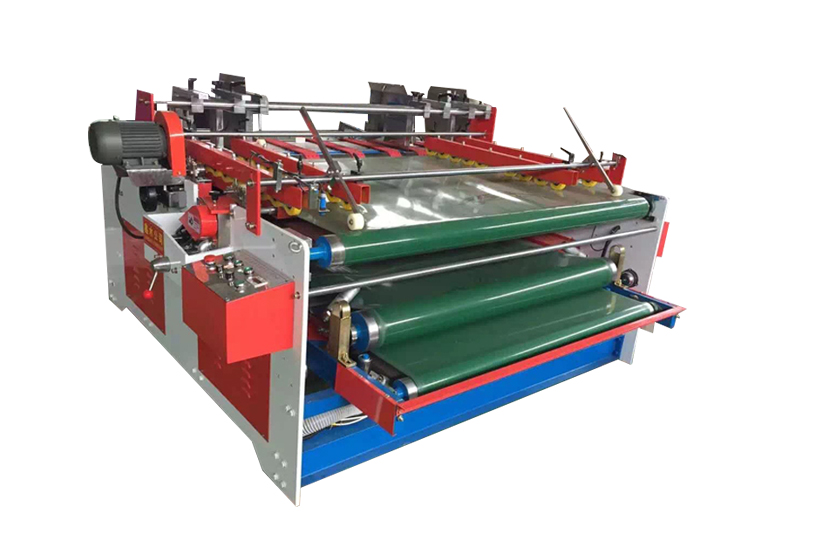

Structural feature:

★The double glue machine is a corrugated paper conveyed from the flyover. After preheating, it is coated again with glue and then pasted into the double-sided machine to paste and bond to produce three-layer five-layer cardboard.

★Frame cast iron structure, stable performance, upper middle layer preheater diameter 400mm, increase paper temperature to facilitate glue paste, double pressure roller design glue evenly, stainless steel glue groove, automatic circulation glue supply.

★after quenched of the glue roller surface,the hole machining, surface grinding and doing balancing engraved anilox pit type, coating evenly, less consumption of plastic.

★The transmission of the glue unit is directly connected by the frequency conversion motor through the reducer, and the frequency conversion control ensures that the linear speed of the glue roller is synchronized with the double-sided machine and can operate independently. Use angle sensor, PLC, touch screen man-machine interface display. According to different paper quality, different speeds automatically control the amount of glue, according to the different corrugated shape automatically adjust the gap between the pressure rollers, without accumulating errors.

Main component parameters:

|

Part name Craftsmanship |

Specification | Surface treatment |

| Glue roller | ¢320mm | Round grinding and pressing pit mesh chrome plating |

| Fixed paste roller | ¢155mm | Round grinding chrome |

| Pressure roller | ¢150mm | Round grinding chrome |

| Paper shaft | ¢128mm | Round grinding chrome |

| Preheating cylinder | ¢400mm | Round grinding chrome |

Main dynamic parameters:

| Name | Power | Voltage | Frequency |

| Rubber roller active motor | 4KW*2 | 380V | 50HZ |

| Glue adjustment speed reducer | 200W | 380V | 50HZ |

| Roller gap adjustment motor | 200W | 380V | 50HZ |

| Rubber pump motor | 2.2KW | 380V | 50HZ |

Main parts brand and origin:

| Serial number | Name of main parts | Brands or place of origin | Remarks |

| 01 | Glue roller and paste roller | Tiangang | 45# steel |

| 02 | Preheat roller | Tiangang or Jigang | Q235B Container board |

| 03 | Bearing | Japan NSK | |

| 04 | Bearing with seat | FuJian | |

| 05 | Pneumatic Components | AirTac | |

| 06 | Low-voltage electrical appliances | SIEMENS | Contactor, relay, button |

| 07 | Glue reducer | Taiwan city-state or Wanxin | |

| 08 | Main reducer | Taiwan city-state or Wanxin | |

| 09 | Touch screen | Taiwan Vinylon or Kunlun Tongtai | 10.4 inch |

| 10 | PLC and inverter | SIEMENS | |

| 11 | Timing belt | Germany OPTIBELT | |

| 12 | Trap | Armstrong, United States | Float |