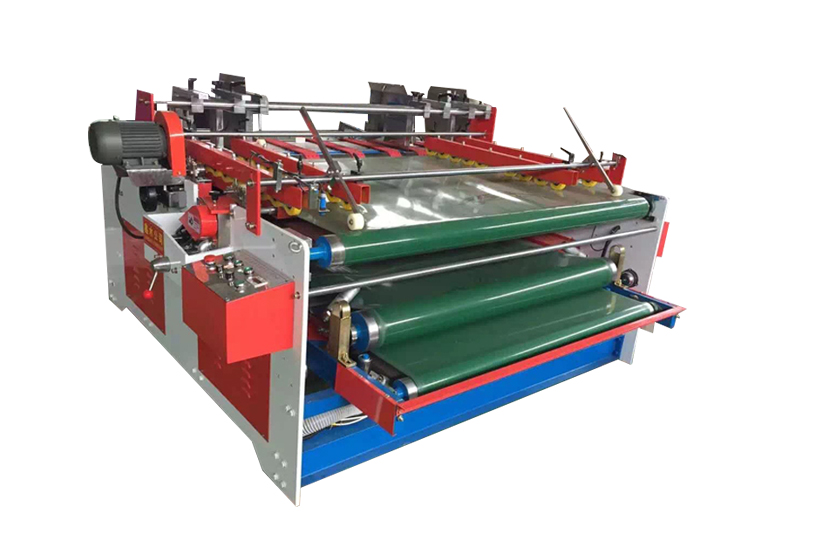

TB-GYS Automatic 5+1 High definition printer slotter die cutter dryer coating machine

Functional features

◇This machine can achievefeeding, printing, drying function one time. It can save operator. It’s a high speed, high efficiency, low consumption of carton production equipment.

◇Human-computer interface, and reserve manual electronic control auxiliary operation function.

◇International famous brand electric parts and computer software was used in the whole machine (Schneider, DELTA). Top quality and steady; computer order storage and adjustment (Beijing Kunlun MCGS color touch-screen), convenient operation, faster order update (It can pre-storethe many orders in the computer)

◇All the transmission axle and roller are made by the high quality steel, temper, thermal refining, and high precision computer dynamic balance correcting; grinded surface and plated with rigid chrome.

◇The driving gear adopt 20CrMnTi ally steel, carburizing and quenching treatment, hardness HRC58-62, with grinding processing, precision level 6, Ensure long time using and tinted with high precision.

◇All connection with keyless between gear and roller, ensuretransmission accuracy.

◇Adopt vacuum feeding in whole process, making paperboard feeding stable

◇Equipped with ceramic roller doctor blade system, making better printing result, precision adjustment system ensure inking ,pressing and other important gap adjustment.

◇Glazing unit and drying unit for option

◇The whole machine undergoes the spray lubrication

◇The mainframe was controlled by frequency conversion (DELTA), start-up, running more smoothlyand energy conservation

◇All the electric part, driving bearing, pneumatic control components, all are national standard.

Main technology:

| NO. | Parameter name | Unit | model |

| 1 | Design speed | Pcs/min | 200 |

| 2 | The maximum size feeding paper | mm | 920×2000 |

| 3 | The minimum size feeding paper | mm | 350×600 |

| 4 | The maximum size of feeding paper by partition | mm | 1000×2400 |

| 5 | The maximum size of printing area | mm | 920×2360 |

| 6 | Printing precision | mm | ±0.25(FOUR COLOR) |

| 7 | Standard plate thickness | mm | 3-6mm |

| 8 | Printing paperboard thickness range | mm | 2-11 |

| 9 | Printing roller adjustment | degree | 360° |

| 10 | Printing roller lateral adjustment | mm | ±10 |

| 11 | Slotting precision | mm | ±1 |

| 12 | Minimum slotting distance ( same direction) | mm | 135x135x135x135 |

| 13 | Minimum slotting distance(opposite direction) | mm | 270x65x270x65 |

| 14 | Maximum slotting depth | mm | 300 |

| 15 | Die cutting precision | mm | ±1.5 |

| 16 | Die cutting knife roller lateral adjustment | mm | ±10 |