Functional features

Technical parameters:

| Working width | 1800mm |

| Design speed | 150m/min |

| Economic speed | 100-120m/min |

| Min. cutting length | 500mm |

| Max. cutting length | 9999mm |

| Cutting accuracy | ±1mm, |

| Working power | 380V 50Hz 53KW |

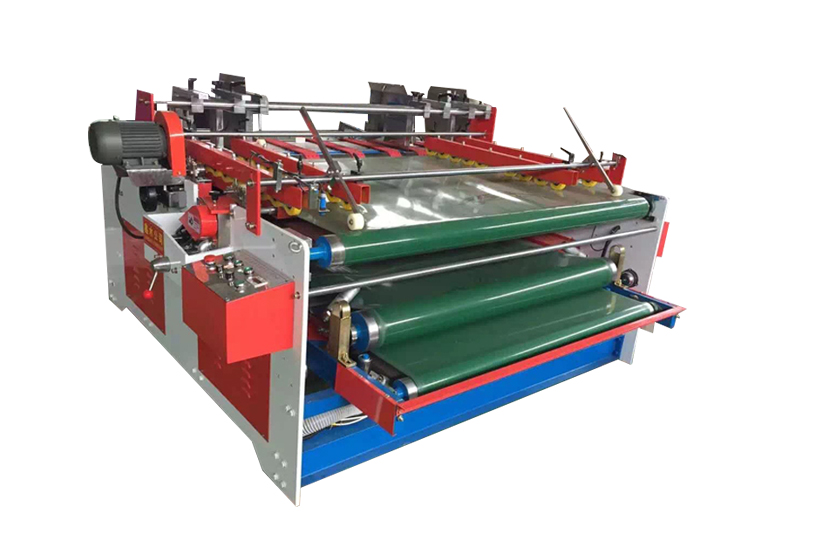

Structural feature:

★It can store 200 units orders,replace the cutter specifications quickly and accurately,changing orders without stop,And enables networked computers to facilitate production management.

★Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy.

★Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blade life.

★Around feed rollers are used the sun gear platen way, smooth delivery, pressure evenly, easy to crush plate board or cause blockage.

★This model is the braking energy storage (non-dynamic braking), so the energy consumption in the production process, the average electricity consumption is 1/3 of an ordinary NC cutting machine, saving more than 70% power to reach the goal of saving money .

★Precision adjustable no gap gear to ensure precise blade engagement, running balance.

★Knife roller: fine quality forged steel material, the balanced, with good stability.

Main dynamic parameters:

|

Part name Craftsmanship |

Specification | Surface treatment | Special treatment |

| Cross cutting the upper and lower knife axis | ¢216mm | Conditioning | Dynamic balance |

| Front lower conveying roller | ¢156mm | Round grinding chrome plating polishing | Dynamic balance |

| Rear lower conveyor roller | ¢156mm | Round grinding chrome plating polishing | Dynamic balance |

| Paper shaft | ¢160mm | Wrapped silicone | Dynamic balance |

| Output sun gear | ¢160mm | Polyurethane | Intensive |

Main dynamic parameters:

| Name | Power | Voltage | Frequency |

| Main drive servo motor | 37KW | 380V | 50HZ |

| Front feed motor | 3KW*2(Frequency adjustment speed) | 380V | 50HZ |

| Rear feed motor | 3KW*2(Frequency adjustment speed) | 380V | 50HZ |

| Lubricating oil pump motor | 0.18KW*2 | 380V | 50HZ |

Main parts brand and origin:

| Serial number | Name of main parts | Brands or place of origin | Remarks |

| 01 | Box rack | Self-produced | HT250 |

| 02 | Knife roll | Tiangang Precision Forging | 42CrMo |

| 03 | Full AC servo motor | Shanghai Futian | 37KW |

| 04 | Paper frequency conversion motor | Siemens Bed | |

| 05 | Flying shear servo control system | Kobe, Germany | |

| 06 | Motion control board | Germany MKS-CT150 | |

| 07 | Rotary encoder | Germany SIKI | |

| 08 | Timing belt | Obi, Germany OPTIBELT | |

| 09 | Tightening sleeve | XianYang ChaoYue | |

| 10 | Bearing with seat | FuJian | |

| 11 | Low-voltage electrical appliances | SIEMENS | Contactor, relay, button |

| 12 | Proximity switch | Omron Japan OMRON | |

| 13 | Frequency converter | SIEMENS | |

| 14 | HMI | Kunlun State | |

| 15 | Sun gear | ShenZhen |