Functional features

Technical parameter and function:

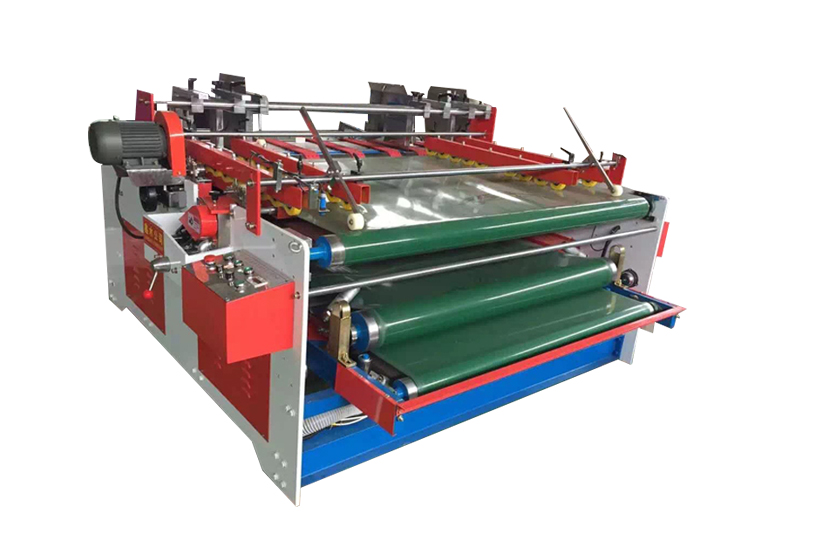

Machinespeed:150m/min

Adopt independent speed changing box, gimbal transmission structure.

effective width:1800mm

diameter of roller:φ320mm

Vacuum suction type single facer. The up and down roller adopt the good quality 48CrMo alloy steel, after heat treatment, the hardness is HRC58°-60°, the surface is after the grinding and chrome treatment.

Closed gear oil immersion lubrication, reduce noise, smooth operation, to extend the service life of the gear.

The upper roller, pressure roller and gules roller go up and down by pneumatic control.

structure feature:

France Schneider brand electric appliance.

The machine Frequency converter control

Adopt absorption feed paper, convenient to use, intermittent slot, corrugating roll deformation coefficient is smaller and more energy-efficient.

Cast iron base flat feet design, more stable operation.

1600 type air vat pressure more stable

Gluer adjustment by manual or electric adjustment, digital display.

Anti-high temperature lube to lubricate the Corrugated Roller and Press Roller’s gears

It adopt electric separating gluer device, pasting department works or stops, it runs independently to prevent depletion of gluer.

Automatic follow the cardboard transmission speed and keeping synchronization.