Functional features

Technical parameters:

| Working width | 1800mm |

| Design speed | 150m/min |

| Economic speed | 100-120mmin |

| Hot plate number | 600mm×18 piece |

| Cooling section length | 5 meters |

| Temperature requirements | 160—200℃ |

| Steam pressure | 0.8-1.3Mpa |

| Air pressure | 0.5—0.6Mpa |

| Pneumatic pressure plate | 14 groups |

| Working power | 380V 50Hz 75KW |

Structural feature:

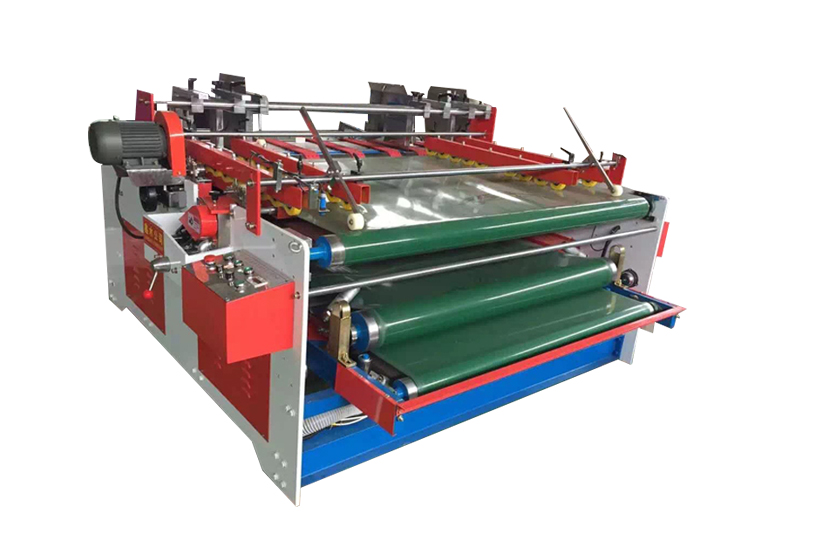

★The double-sided machine is a glued single-sided corrugated paper and facial paper laminated, heated platen heating, glue paste, stereotypes to produce flat cardboard.

★Surface of hot plate is dealed with grinding, hot plate width600mm,in total 20 pieces hot plate,Minister cooling stereotypes 5m.

Hot plate is made adopt container board, enclosed pressure container certificate and inspection certificate.Internal thermal panels for partition isolation structure,s-shaped flow of steam, Steam, water separation function apparent,improve the using rate of steam.

★The hot plate adopts pneumatic pressure plate structure. The pressure plate lifting adopts pneumatic structure. 14 sets of spring pneumatic pressure plates are standard.

★The heat pipe of the heating plate controls the temperature in multiple sections and has a temperature display.

★The upper cotton webbing is automatically centered by the correcting pneumatic valve, and the double cylinder is used to control the S-shaped cotton web tensioning device. The amount of tightening is large.

★The lower belt adopts pneumatic tensioning mechanism, the structure is simple and practical, the left and right of the lower conveyor belt is automatically corrected and aligned, and it can also be adjusted manually on both sides.

★Gearbox drive unit using an independent structure, gear steel ZG-500 number for materials, the use of oil-immersed gear lubrication.

★Electrical components used internationally renowned brands, the device stable and reliable operation.

★Main drive motor for the motor frequency energy, low-speed torque, wide speed range, reliable, easy maintenance.

★The main backbone of high intensity profiles GB, solid structure, beautiful appearance, suitable for high speed working.

Main component parameters:

| Part name

Craftsmanship |

Specification | Surface treatment |

| Upper drive rubber roller | ¢800mm | Covered with wear-resistant rubber |

| Lower drive rubber roller | ¢600mm | Covered with wear-resistant rubber |

| Front and rear driven belt roller | ¢215mm | Round grinding chrome plating polishing |

| Top tension roller | ¢155mm | Round grinding chrome plating polishing |

| Upper belt adjustment roller | ¢130mm | Round grinding chrome plating polishing |

Main dynamic parameters:

| Name | Power | Voltage | Frequency |

| Main drive motor | 75KW | 380V | 50HZ |

Main parts brand and origin:

| Serial number | Name of main parts | Brands or place of origin | Remarks |

| 01 | Main skeleton | Tiangang or lai gang production profiles | NO.36channel and NO.16 I-beam |

| 02 | Drive wallboard | HeBei HanDan | Q345 |

| 03 | Heat board | Tiangang or Jigang | Q235B container board made |

| 04 | Main drive motor | Siemens Bed | 75KW Frequency motor |

| 05 | Cotton webbing | ShenYang | Cotton webbing thickness:9mm |

| 06 | Trap | Armstrong, United States | Float |

| 07 | Low-voltage electrical appliances | SIEMENS | Contactor, relay, button |

| 08 | Pneumatic Components | AirTac or sono | |

| 09 | Frequency converter | SIEMENS | |

| 11 | Bearing | Japan NSK | |

| 12 | Bearing with seat | FuJian |