TB-FAHS 150-1800-Ⅱtype five layer corrugated cardboard production line

Functional features

Main technical parameters and requirements in production line

| 1 | Effective width | 1800mm | 2 | Design produce speed | 150m/min | |||

| 3 | Three layer economic speed | 130-150m/min | 4 | Five layer economic speed | 100-120m/min | |||

| 5 | Seven layer economic speed | ——————- | 6 | Maximum order change speed | 100m/min | |||

| 7 | Longitudinal separation accuracy | ±1mm | 8 | Cross-cutting precision | ±1mm | |||

|

note |

Speed the above targets required to achieve:effective width1800mm,Comply with the following standards and ensure the paper’s equipment condition 175 ℃ heating surface temperature. | |||||||

| Top paper index | 100g/㎡–180g/㎡ Ring crush index(N.m/g)≥8 (Water containing8-10%) | |||||||

| Core paper index | 80g/㎡–160g/㎡ Ring crush index(N.m/g)≥5.5 (Water containing8-10%) | |||||||

| In paper index | 90g/㎡–160g/㎡ Ring crush index(N.m/g)≥6 (Water containing8-10%) | |||||||

| 9 | Flute combination | |||||||

| 10 | Steam requirement | The maximum pressure 16kg/cm2 | Common pressure10-12kg/cm2 | use4000kg/Hr | ||||

| 11 | Electricity demand | AC380V 50Hz 3PH | Total power≈350KW | Running Power≈150KW | ||||

| 12 | Compressed air | The maximum pressure 9kg/cm2 | Common pressure4-8kg/cm2 | use1m3/min | ||||

| 13 | Space | ≈Lmin90m*Wmin12m*Hmin5m(The actual drawing to provider to provide audited prevail) | ||||||

Customer owned section:

1、Steam heating system:proposal with 4000Kg / Hr of a steam boiler. Pressure:1.25Mpa steam pipeline.

2、Air compressed machine、air pipeline、glue conveying pipe.

3、Power supply、wires connected to the operation panel and line pipe.

4、Water sources、water pipelines、buckets and so on.

5、Water, electricity, gas flush mounting civil foundation.

6、Test with the base paper、corn starch (potato)、Industrial use caustic soda、borax and other material.

7、Oil equipment、lubricating oil、hydraulic oil、lubricating grease.

8、installation、commissioning of food, accommodation。And provide installers with the installation.

| Corrugated machinepro ject list and price

TB-FAHS 150-1800-Ⅱtype five layer corrugated paperboard production line |

||||

| Specification | Equipment name | QTY | Remark | |

| ZJ-V6B | Hydraulic shaftless mill roll stand | 5set | Spindle ¢270mm, hyperbolic heavy rocker, toothed chuck , multi-point brake, hydraulic drive lifting, panning left and right on the middle.Pneumatic ejector. | |

| YXC | Hydraulic pressurePaper system | 10set | Double groove width 10m. guide rail length and the ground level, on the double position paper design, hydraulic clamp for paper, paper unloading hydraulic push rod save manpower, hydraulic motor traction feeding trolley. | |

| JZJ | Automatic splicer | 5set | Automatic splicer keep corrugating cardboard assembly line uninterrupted work,Reduce paper consumption,Greatly improve productivity.Maximum speed 250m/min | |

| RG-1-10B | Top paper preheat cylinder | 2set | Roller ¢1000mm, including pressure vessel certificate. Adjust the wrap angle electrically. The wrap angle can adjust the heated area of the paper within 360°. The angle of wrap is automatically adjusted according to the speed of the vehicle, the angle of the wrap angle is displayed on the touch screen, and the parking automatically returns to zero to facilitate paper penetration. | |

| RG-1-10B | Core paper preheat cylinder | 2set | Roller ¢1000mm, including pressure vessel certificate. Adjust the wrap angle electrically. The wrap angle can adjust the heated area of the paper within 360°. The angle of wrap is automatically adjusted according to the speed of the vehicle, the angle of the wrap angle is displayed on the touch screen, and the parking automatically returns to zero to facilitate paper penetration. | |

| SF-405E | Multi-cassette positive pressure single facer | 2set | Main corrugating roller ¢405mm,corrugating roller group flute quick change.corrugated roller with spraying tungsten carbide dealing.with maintenance-free airbag loading,PLC automatic control glue, HMI touch screen, Breaks automatic parking relief. | |

| DY-C

|

Electric hydraulic roller change forklift | 1set | Large capacity battery, power walking, hydraulic lift, centralized control. | |

| MK-405 | Corrugating roller quick change

Module |

1set | Corrugating roller diameter:405mm,with tungsten carbide dealing,Modules including:Both ends of the shaft seat、bearing、steam element、Suction box、Pneumatic components assembly. | |

| RG-3-10B | Triple preheater | 1set | Roller ¢1000mm, including pressure vessel certificate. Adjust the wrap angle electrically. The wrap angle can adjust the heated area of the paper within 360°. The angle of wrap is automatically adjusted according to the speed of the vehicle, the angle of the wrap angle is displayed on the touch screen, and the parking automatically returns to zero to facilitate paper penetration. | |

| GM-30 | Double glue machine | 1set | Glue roller diameter 320mm。Frequency motor drive, PLC control. Glue quantity PCL automatic adjustment,HMI touch screen display. | |

| TQ-A | Conveyor bridge | 1set | 200mm main beam channels, independent inverter motor drive pull paper feed, adsorption tension.Electric correction. | |

| XG-JP | Automatic correction | 1set | No power correction model save energy.High precision sheet correction. Paper width change does not require any adjustment

Full width infrared detection curtain。Reduce paper waste generated tear。reduce the waste of paper edge not to precision. |

|

| SM-E | Double facer | 1set | The frame is 400 mm national standard channel steel, chrome plated hot plate 600 mm *18 pieces, the entrance uses arc-shaped hot plate to make the facial paper heat up extremely quickly, and the design structure of the whole pressure plate is touched. PLC automatically controls the pressure plate. The upper and lower belts have automatic deviation correction, temperature display, and frequency conversion motor. The PID automatic temperature control system is used to link the three-layer and five-layer automatic control of the number of temperature hot plates, which is highly efficient and energy-saving. | |

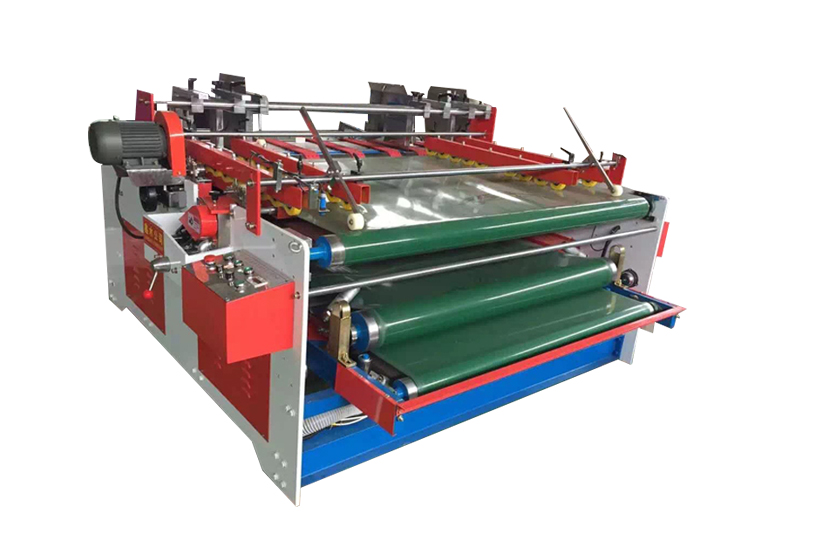

| NCBD | NC thin blade slitter scorer | 2set | Tungsten alloy steel, seven knives twelve lines,zero-pressure line type. Schneider servo computer automatically discharge knife, suction outlet width automatically adjusted.Closed electric control box, plus air conditioning and dehumidification. | |

| NC-25D | Double NC cutter helical knives | 1set | Full AC servo control, energy storage brake, helical blade structure, oil-immersed gears,10.4-inch touch screen display.Closed electric control box, plus air conditioning and dehumidification. | |

| DML-200 | Automatic large gantry stacker | 1 set | Servo drive platform lift, four sections of frequency transmission, automatic points in batches, automatic stacking discharge, imported high-strength belt output,out paper side standard transport aircraft. | |

| DM-XLM | Automatic small gantry stacking machine | 1set | Servo-driven platform rises and falls, five-stage frequency conversion conveying, automatic counting and stacking discharge, imported high-strength belt output, and standard delivery frame on the paper side. | |

| SG | Production Management System

(complex) |

1set | Improve the automation of production lines,easy to operate.reduce consumption,Improve the utilization of the base paper,save costs. Automatic control production line,stable quality cardboard.Increase the average speed,Increase productivity.Automatic statistics production ,Easy to keep control of the production line, improve efficiency. | |

| ZJZ | Glue station system | 1set | Customers -owned pipeline.Glue configuration is composed by carrier tank、main tank、storage tank、and send plastic pump、back plastic pump. | |

| QU | Gas source system | 1set | Gas source is prepared by the customers. | |

| ZQ | Steam system | 1set | Steam system components used in all GB valves.Including rotary joint,upper and lower dispenser.traps,pressure table and so on.Customer-owned boilers and pipes. | |

| DQ | Electrical control cabinet system | Electronic control system::fingerless single facer、driving part、NC thin blade slitter scorer、double facer、glue machine all adopt frequency motor,delta frequency control system.operation interface easy and convenient,Speed display control cabinet with each unit speed display, the unit call, emergency stop function.The main contactor by French Schneider (Schneider) famous brand products, the main motor adopts SIEMENS, main bearing by Japan NSK, main inverter, PLC by SIEMENS. | ||

| TB-FAHS 150-1800 Five PLY Corrugated Production Line | Fob(Tianjin port): $445000 | |||