Functional features

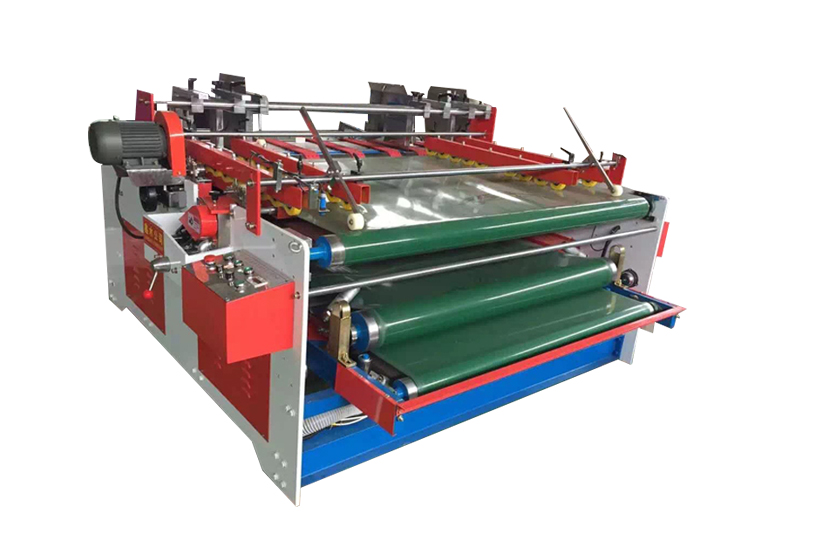

Feeding department:

◇Paper feeding : Chain, paper pushing feeding .

◇Can attached with the automatic feeding unit.

printing department:

◇printing roller , paper feeding roller, pressureroller , all the surfaces grinding , hard chraminum plating , balance correction . stable operation .

◇Ratchet wheel fixed scroll can achieve fast changing plate.

◇Paper feeding pressure, printing pressure, transmission pressure , auto-locked adjustment .

◇Metal anilox roller ( adopts domesticfamous professional produced one , 180 wire-280 wire)

◇The rubber roller adopts famous domestic brand ( 80% natural rubber )

◇Phase adjustment by planetary ( no matter working or stopping )

◇Pneumatic lifting and down the anilox roller , auto ink distributing .

◇Main gear adopts free-key connection , can long-time keep the printing accuracy.

◇The driving gear oiled manual focus .

Slotting department

◇The up and down pressing the line roller , the up and down slotting roller , surfacegrinding , hard chraminum plating , balance correction , stable operation .

◇The slotting knives pedestal can be worm-type adjustment according to the thickness of cardboard. ( three-layer , five-layer and seven-layer)

◇The creasing knife pedestalworm-type up and down adjustment according to the thickness of cardboard。( three-layer, five-layer and seven-layer )

◇The back slotting knife ( height of box) ,four knives adjustmentsynchromous , easy working .

◇The main gear adopts free-key connection , can maintain the long-time slotting accuracy.

◇Electric department of each unite , pneumatic locking .

◇Phase adjustment by planetary ( no matter working or stopping ) , Micro-computer automatically adjusts the number of NC)

◇The back of machine equipped with electric swith , can correct the slotting position and other functions .

Die-cutting department

◇Die-cutter phase is adjusted through computer and digital electric control

◇Die-cutting knife horizontal adjustment undergoes the computer and digital and electric control of a scope of 5mm.

◇Glue roller cutting and trimming facilities include the cushion able to be used for many times and save the cost in a great deal.

◇Cushion roll adopts high -quality steel, grind the surface and do the hard chrome plating,diameter 480mm

◇The cushion rollers mechanical, horizontal cam facility of a scope of 35mm prolong the lifespan of the die-cutting cushion.

◇Automatic to adjust the distance between cushion roll and knives roll

◇Automatic to adjust the distance between cushion roll and down roll

◇Automatic lathe the cushion to reduce the pressure of die-cutter.

◇Diameterof pass paper axle :86mm,adopt high quality steel .

Technical parameters:

| Model | TB480 |

| Wall diameter(mm) | 3100 |

| Max. paper coverage area | 1450×2800 |

| Effective printing area | 1450×2600 |

| Finish speed(pieces/min) | 0-80 |

| Power of main motor | 4.0 |

| Thickness of printing plank(mm) | 3-7 |