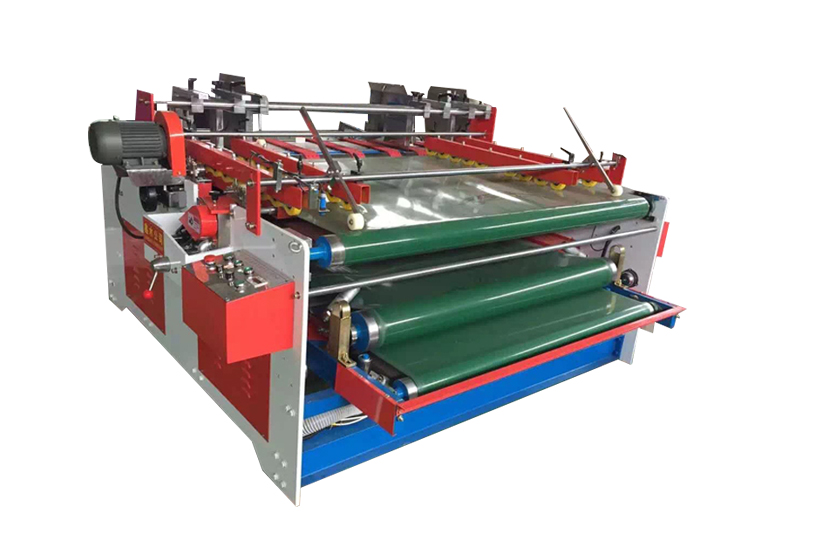

BF-Thin blade slitter scorer machine

Thin blade slitter scorer is the replacement of original slitter scorer with thick angel cutting knives.The corrugated paperboard cut by this machine has incision edges smooth,clean, straight flute,No Degumming ,Improve the quality of the appearance of slit.

The cutting knives is equipped with grinding device,keep the thin blade edge sharp;Each thin blade can be adjusted alone turning depth,can make the new and old blade of turning depth consistent adjustment.or make some blade out of slitting work as the requirement.

This machine run smoothly,low noise,good slitting paperboard quality,is the ideal equipment of the users to improve the competitive ability of the carton

Functional features

◇Thin blade slitter scorer adopts electromagnetic infinitely adjustable-speed motor driver,using level 1 V belt and chain transmission,passing the power to the creasing wheel,slitting thin blade and guiding roll.Creasing wheel can use hand toggle along the axial movement,when the creasing position is determined,fasten the holding screw of the creasing wheel.The down creasing wheel sometimes need jigger,when the holding screw comes out,it can be axial adjusted

◇The slitting thin blade group is fixed on the front end of the compound rest.the back-end of compound rest and tool carriage is Set on the six-party shaft by large synchronous belt wheel.the compound rest and tool carriage hanging on the rack shaft,insert the gear adjusting spanner into regulation hole of pressing sleeve big support,move the knife set right and left.But before the adjustment,loosen the fastening screw of clamp set,when the thin blade’s position is OK,fastening the fastening screw bolt

◇A pair of knife grinding wheel is set above the diagonal of the thin blade,move up and down by the pneumatic cylinders,Grinding wheel downward when in contact with the rotating thin knife to sharpen.The machine set the manual mode and automatic sharpening two functions,to keep thin mouth of sharp edge

◇When loosen the fastening screw bolt of large and small stents,can rise or fall the thin blade.when working, thin blade entrance into the down toolsection 1.5-2mm is OK.If entrance too deep,it’s easy to bring forth deckle edge.If a group of thin blade does not need to participate in work, can lift this thin knife.

◇Four air throttle valve is equipped on the upper separator of the machine,controlling 4 set of knife grinding wheel cylinder gas supply respectively.closing some air throttle valve can stop this cylinder work.Usually the 4 air throttle valve is opened entirely,only in one knife set is lift does not work, the corresponding air throttle valve can be closed.

◇When the blade needs automatic sharpening,dial the rotating knob to auto position,at this point stop grinding time and grinding time can be set,Grinding wheel automatic sharpening or stop according to set time;When need to manual mode,dial the rotating knob to manual position,press the inching shapen button,wheel downward starts shapen.when the hand leave the button,the grinding wheel return back.

◇The adjustment of the grinding wheel should be carried out in the stop state,loosen the two fastening bolts of the grinding wheel carriage,Move the cylinder to make the lower edge of the two grinding wheel and thin blade edge have 1.5mm gap,then fasten the cylinder. Put internal hexagonal wrench(Hexagonal 6 mm) flat between the cylinder and grinding wheel,to make the two wheel plane access to the thin blade mouth,fasten the grinding wheel group,remove the M8 inner hexagon spanner,The position of the grinding wheel is OK now.Cylinder gas pressure should be adjust in the range of 0.3 to 0.4 Mpa

◇The gap of upper and lower creasing wheel and the upper and lower guide roller adopts eccentric gear adjustment.Loosen the tightening screw of the top tight regulation shaft at the side panel,Using a wrench rotate hexagon of the regulating shaft,to adjust the paper gap of the up and down creasing wheel(or up and down guide roller),Fasten fastening screw when the adjustment is OK.

Main technical parameters:

| Model | BF1800 | BF2000 | BF2200 | BF2500 |

| Range between walls | 1800 | 2000 | 2200 | 2500 |

| Max. Slitting width | 1700 | 1900 | 2100 | 2400 |

| Min. Slitting width | 180 | |||

| Min slitting length | 470 | |||

| Min. Creasing width | 60 | |||

| Max. Speed | 130 | |||

| Slitting numbers | Four knife or according to user requirements | |||

| Creasing numbers | Six lines or according to user requirements | |||

| Processing cardboard thickness | 2.5~10 | |||

| Motor power | 3.0 or 4.0 | |||